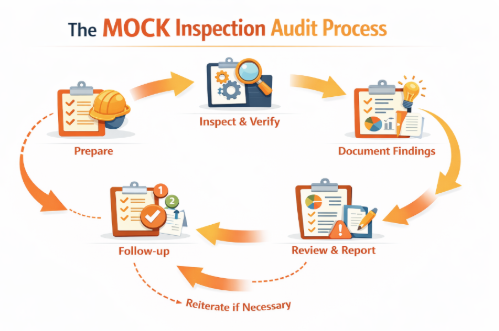

Demonstrating commitment to your organization’s overall Quality and Compliance Program can feel daunting. Defining specifics as well as timelines, goals, and operating costs can seem larger-than-life. To streamline the available avenues, this piece aims to examine the Mock Inspection method as a means to promote Regulatory Inspection Readiness within the organization.

Demonstrating Regulatory Inspection Readiness should be actionable, evidence-based, and well documented. By integrating a Mock Inspection, teams will endeavor to mirror responses and actions to regulators in real-time. A popular method, the Hats-On/Off Mock approach, offers a scenario-based Mock Inspection reconstruction where assessors carrying out the roles of Regulators (Hats-On) simulate what can be expected during the actual Health Authority Inspection. The contrast is to offer on-the-spot coaching and re-direction to further Auditee development (Hats-Off).

This scenario is intended to gauge not only compliance, but auditee responses and behavioral components during a Regulatory Inspection. Staff, Subject-Matter-Experts (SMEs), back-room team members, Hosts and Front Room attendees should aim to maintain the simulation and act as if the scenario were live.

Across the Inspection, Quality leaders and auditees should strive to standardize roles, responses as well as adhere to any established Inspection policies as well as develop teams to describe complex Organizational changes or situations: